Unlocking Innovation: The Impact of Digital Twins on Automotive Design and Engineering

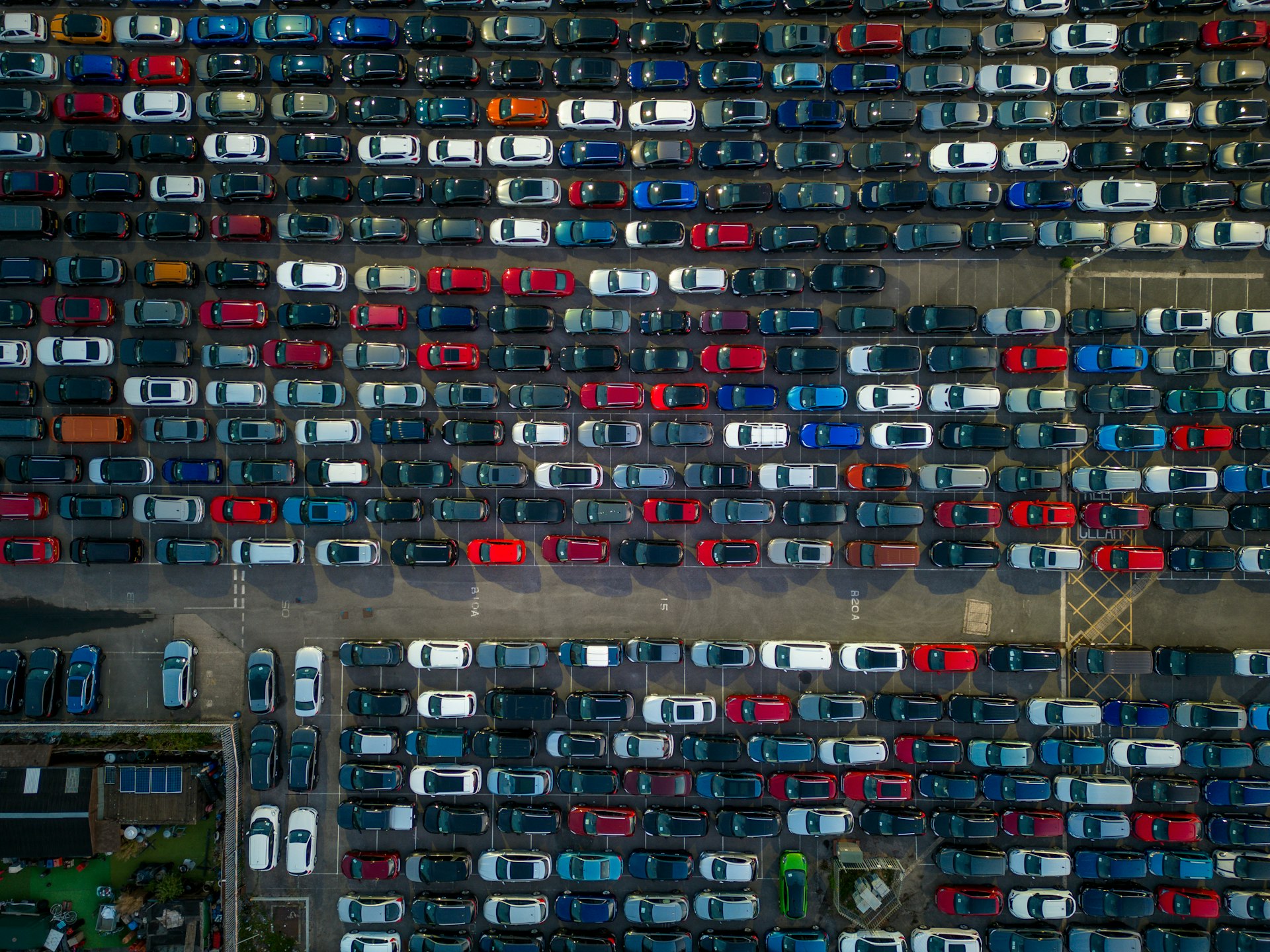

Photo by Brian Matangelo on Unsplash

Introduction: The Digital Twin Revolution in Automotive Design

Automotive design is undergoing a profound transformation powered by digital twin technology . This innovation creates real-time, data-driven virtual replicas of physical assets, allowing manufacturers to simulate, analyze, and optimize vehicle design at every stage. The impact of digital twins is seen in faster prototyping, cost reductions, improved safety, and a more agile response to evolving market demands. This article explores the specific benefits, real-world examples, implementation strategies, and guidance on accessing digital twin solutions in the automotive sector.

What Are Digital Twins-and Why Do They Matter in Automotive?

A digital twin is a virtual model of a physical object, system, or process, continuously updated with real-world data. In automotive design, digital twins encompass everything from entire vehicles to electronic components. Unlike static 3D models, digital twins evolve alongside their physical counterparts-enabling predictive simulation, performance analysis, and iterative design refinement.

For automotive manufacturers, this means:

- Accelerated development cycles and rapid prototyping

- Reduced reliance on costly, time-consuming physical prototypes

- Improved product quality and reduced risk of late-stage errors

- Enhanced collaboration across global engineering teams

Digital twins are not just a technological upgrade-they represent a shift toward data-driven, agile, and customer-focused automotive innovation [1] .

Key Benefits of Digital Twins in Automotive Design

1. Virtual Prototyping and Faster Iteration

Historically, developing new vehicles required multiple rounds of physical prototypes-each iteration bringing significant cost and delays. Digital twins allow engineers to test, refine, and validate designs entirely in the virtual realm, slashing development time and cost. For example, Volkswagen uses digital twins to simulate and optimize electric vehicle battery performance before any physical build occurs [1] .

Photo by Octavian Stan on Unsplash

Practical steps to implement virtual prototyping include:

- Building high-fidelity 3D models of vehicle systems

- Integrating real-world sensor data for accurate simulation

- Running AI-driven simulations for stress, thermal, and safety scenarios

- Iterating designs rapidly based on simulation outcomes

These methods enable the exploration of new concepts without the risk or expense of traditional prototyping.

2. Improved Engineering Precision and Safety

Digital twins allow for comprehensive engineering simulations, from crash testing to thermal management and materials analysis. By integrating physics-aware models and real-time data, manufacturers can:

- Predict structural integrity and failure points

- Validate electrical and electronic components for durability and compliance

- Enhance vehicle safety by identifying issues before production

For example, Ford used digital twins to design a headlight system that enhances night driving safety by simulating how light interacts with various road conditions-resulting in a more reliable and effective product [4] .

3. Cost Reduction and Sustainability

Reducing the need for physical prototypes and tests translates into significant cost savings. Digital twins also help minimize waste by optimizing materials usage and manufacturing processes. Renault, for instance, reduced its vehicle design time from a full year to just one quarter by leveraging digital twin simulations at the earliest design stages [4] .

Additionally, digital twins make it easier to test lightweight materials and eco-friendly designs for structural and safety compliance, supporting broader sustainability goals.

4. Enhanced Collaboration and Traceability

Automotive design is a multidisciplinary effort. Digital twins provide a single, up-to-date source of truth, enabling global teams to collaborate in real time. Cloud-based digital twin platforms-such as BMW’s use of the NVIDIA Omniverse-allow engineers, designers, and manufacturers to work on the same virtual vehicle, regardless of location [1] .

This approach reduces errors from miscommunication, accelerates decision-making, and ensures all changes are traceable and integrated across the entire design and production chain.

5. Predictive Maintenance and Lifecycle Management

Digital twins extend beyond design and manufacturing, enabling predictive maintenance and real-time monitoring of vehicles after they hit the road. Tesla, for example, creates a digital twin for each car sold, continuously updating it with sensor data to identify maintenance needs and optimize performance [4] .

This feedback loop allows automakers to:

- Proactively address service issues before failure occurs

- Continuously improve product design based on real-world usage

- Enhance the customer experience and reduce warranty costs

Real-World Case Studies and Applications

BMW: The company uses digital twins to create “smart factories” where production lines are simulated and optimized, reducing waste and ensuring high-quality output [1] .

Ford: Leveraged digital twins to design advanced lighting systems, using simulations to perfect the behavior of headlights in various driving conditions [4] .

Renault: Cut vehicle design time dramatically by conducting extensive virtual testing before physical prototyping [4] .

Nissan: Uses predictive digital twins to optimize production and spot bottlenecks, maintaining efficiency and saving on costs [4] .

These cases illustrate the tangible returns of adopting digital twin technology-shorter development cycles, higher quality, and improved operational efficiency.

Implementation Strategies: How to Access Digital Twin Solutions

Automotive businesses interested in adopting digital twin technology can follow these steps:

- Assess Needs and Objectives: Identify which aspects of your design, engineering, or production process could benefit most from digital twin technology. Consider areas with high costs, frequent design changes, or complex system integration.

- Choose the Right Platform: Investigate established digital twin solution providers that offer tools tailored to automotive needs. Leading technology companies such as NVIDIA Omniverse and Siemens Digital Industries Software provide digital twin platforms with automotive applications. For up-to-date information, visit their official websites, search for “digital twin automotive solutions,” or contact their sales departments for demos and consultations.

- Integrate with Existing Systems: Ensure your digital twin solution can communicate with CAD, PLM, and manufacturing execution systems already in use. Most providers offer integration guides and support.

- Start with Pilot Projects: Before a full-scale rollout, launch a pilot project focusing on a specific vehicle component or design challenge. Gather data, measure improvements, and refine your approach.

- Engage Cross-Functional Teams: Digital twins deliver the most value when engineers, designers, quality assurance, and manufacturing teams collaborate. Establish processes for continuous feedback and shared ownership.

To access digital twin expertise or platforms, you can:

- Contact major industrial technology vendors through their official websites

- Attend industry events and conferences focused on automotive digital transformation

- Search for “digital twin consulting for automotive” to find specialized service providers

- Engage academic partners or industry groups for pilot research collaboration

Challenges and Considerations

While the benefits are substantial, digital twin adoption presents challenges, including:

- Data Integration: Aggregating and synchronizing real-time data from multiple sources

- Cybersecurity: Ensuring digital twins and underlying systems are protected from cyber threats

- Scalability: Managing the complexity of large-scale implementations across global operations

- Regulatory Compliance: Addressing privacy, safety, and industry-specific regulations

Manufacturers typically address these issues by starting small, using robust platforms, and building internal expertise over time. Consulting with established technology partners can also help navigate these challenges.

Alternative and Complementary Approaches

While digital twins are rapidly becoming central to automotive design, complementary technologies-such as AI-driven simulation, augmented reality (AR) for collaborative design reviews, and IoT sensors for real-time monitoring-can further enhance effectiveness. Manufacturers may combine these tools to create a holistic digital engineering environment.

Step-by-Step Guidance to Explore Digital Twin Solutions

- Identify your organization’s primary design and engineering pain points.

- Research leading digital twin solution providers and request case studies relevant to automotive design.

- Discuss with technology partners or consultants about integration requirements, costs, and pilot project planning.

- Consider forming partnerships with academic institutions or industry groups to share knowledge and resources.

- Monitor industry publications and events for updates on best practices and emerging technologies in digital twins.

For further learning, you can search for terms such as “automotive digital twin case studies,” “digital twin platform for vehicle design,” or “digital twin simulation software automotive” to find detailed resources from established companies and academic sources. If you work with a major automotive OEM or supplier, consult your organization’s R&D or IT departments for internal digital twin initiatives and available support.

Conclusion: Driving the Future of Automotive Design

Digital twin technology is reshaping how vehicles are imagined, designed, tested, and supported. By enabling rapid iteration, predictive validation, and seamless collaboration, digital twins empower automakers to deliver safer, more efficient, and innovative vehicles. Organizations looking to access these benefits should begin with targeted pilot projects, leverage established technology partners, and cultivate a culture of continuous digital innovation.

References

- [1] AT&T (2023). The Role of Digital Twin Technology in the Automotive Industry.

- [2] Globant (2023). The Strategic Role of Digital Twins in Automotive.

- [3] Molex (2023). Predictive Automotive Electronics Performance with Digital Twins.

- [4] TXOne (2023). The Digital Twin Automotive Revolution: An Ultimate Guide.

- [5] IIoT World (2023). The Digital Twin in Automotive: The Update.

MORE FROM smartsavingsfinder.com