Transforming Automotive Production: The Expanding Role of Robotics in Assembly Lines

Photo by Alber on Unsplash

Introduction

The automotive industry is experiencing a profound transformation as robotics become integral to assembly line operations. Once limited to repetitive tasks, today’s robotic systems deliver unmatched efficiency, precision, and flexibility. For manufacturers and suppliers, understanding the evolving role of robotics is essential for maintaining competitiveness and meeting the demands of modern vehicle production.

The Evolution of Robotics in Automotive Assembly

Robotic automation in automotive assembly dates back to the 1980s, when simple pick-and-place machines began handling repetitive, labor-intensive tasks. Over the decades, advancements in robotics, sensor technology, and artificial intelligence have dramatically increased capabilities. Modern assembly lines now integrate robots for tasks ranging from welding and painting to intricate component assembly and quality inspection [1] [5] . This integration has allowed manufacturers to boost productivity, reduce errors, and create safer, more dynamic production environments.

Key Applications of Robotics in Automotive Assembly Lines

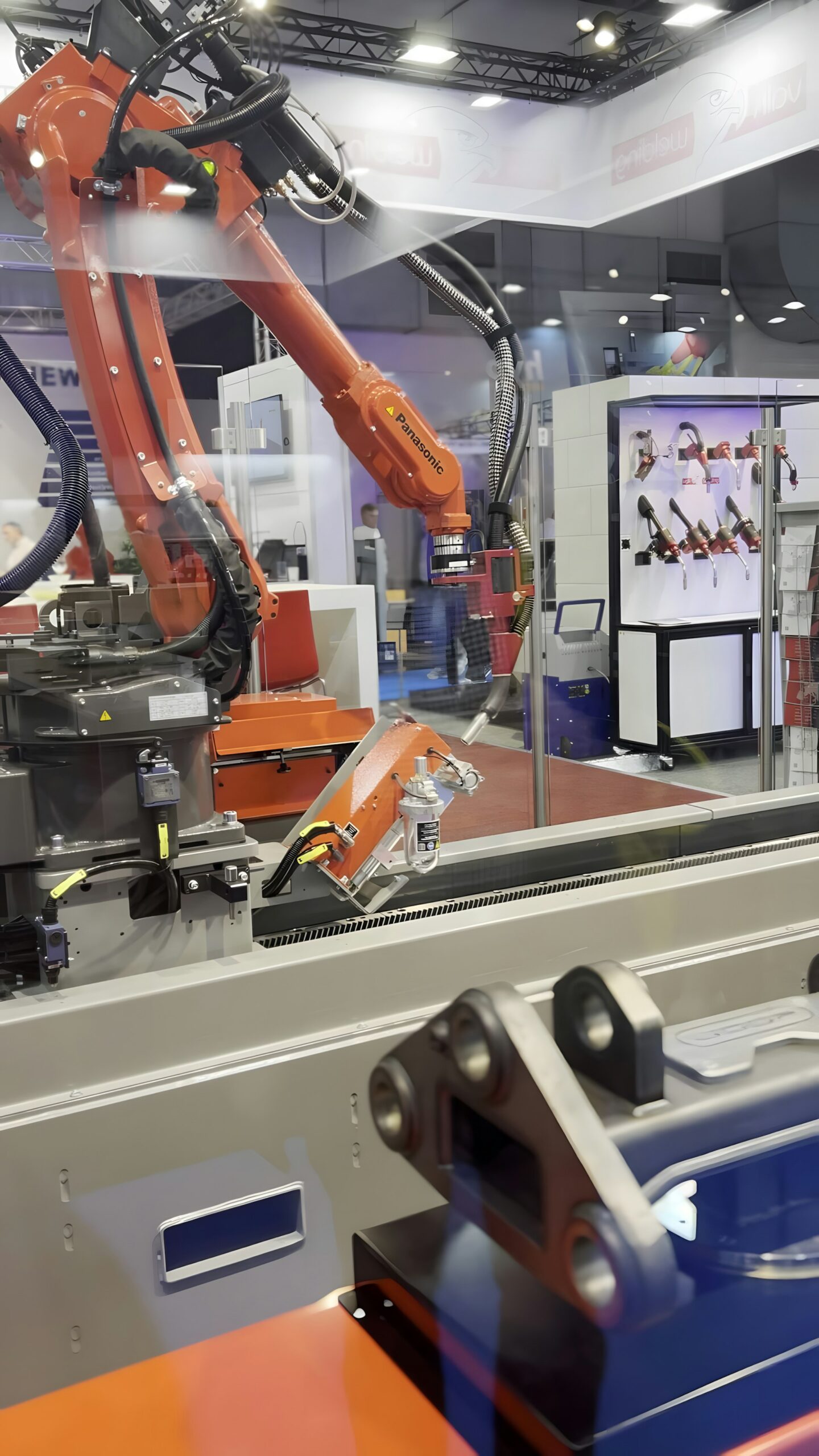

Welding and Painting

Robots have long excelled in welding and painting applications. Robotic welding ensures consistent, high-quality joints by precisely controlling torch orientation and arc parameters for each cycle. This not only improves structural integrity but also reduces the risk of workplace injuries by removing human workers from hazardous environments [4] . Paint robots deliver flawless, uniform coatings while minimizing waste and supporting environmental compliance [2] .

Component Assembly and Installation

Modern robots assemble small and delicate automotive components with remarkable precision. Tasks such as screwdriving, windshield installation, and wheel mounting are now routinely performed by robotic arms, ensuring consistent quality and reducing assembly errors [4] . For example, Ford has implemented collaborative robots (“cobots”) to assist with component assembly, improving overall efficiency and flexibility [5] .

Material Handling and Transfer

Robots streamline the movement of raw materials, parts, and finished products throughout the assembly process. They handle heavy lifting, repetitive transfers, and palletizing tasks that would otherwise be physically demanding or hazardous for human workers. This improves workplace safety and reduces downtime due to injuries [2] .

Quality Control and Inspection

Equipped with advanced vision systems, robots now play a critical role in quality assurance. Automated inspection robots can detect defects in real time, ensuring each vehicle component meets stringent standards before leaving the assembly line. This reduces the number of defective units, minimizes recalls, and supports regulatory compliance [5] .

Collaborative Robotics: Human-Robot Partnership

The rise of collaborative robots (cobots) marks a significant shift in automotive manufacturing. Unlike traditional industrial robots restricted to caged zones, cobots are designed to work safely alongside human operators. With force-limiting technology and advanced sensors, cobots can detect unexpected contact and halt operations instantly, protecting workers [1] [3] . This enables manufacturers to assign physically demanding, repetitive, or ergonomically challenging tasks to robots, while human workers focus on complex problem-solving and final assembly processes.

Benefits of Robotics in Automotive Assembly

Robotic automation delivers several measurable advantages:

- Enhanced Productivity: Robots operate continuously without fatigue, significantly increasing production throughput.

- Superior Quality: Automated systems ensure consistency, reducing variability and minimizing defects in final products.

- Workplace Safety: Robots manage high-risk, repetitive tasks, reducing workplace injuries and associated costs.

- Operational Flexibility: Advanced robots can be reprogrammed for new models or tasks, supporting just-in-time manufacturing and rapid product changes.

- Cost Efficiency: Although initial investment can be significant, long-term savings are realized through reduced labor costs, lower error rates, and decreased waste [2] [5] .

Implementation: Integrating Robotics into Automotive Assembly

Successfully integrating robotics into an automotive assembly line involves careful planning, investment, and ongoing optimization. Here are step-by-step guidelines for manufacturers considering robotic solutions:

Photo by Homa Appliances on Unsplash

- Assess Process Needs: Identify repetitive, hazardous, or high-precision tasks that could benefit from automation. Consult with experienced system integrators for a comprehensive workflow analysis.

- Select Appropriate Robotics: Choose robots based on payload, reach, speed, and required precision. Consider whether traditional industrial robots, cobots, or specialized machines best suit your needs.

- Plan for Integration: Work with automation experts to ensure seamless integration with existing production lines. Factor in connectivity, safety systems, and compatibility with other equipment.

- Train Personnel: Provide training for operators and maintenance staff to ensure safe and efficient robot use. Many organizations offer certification programs for robotics technicians.

- Monitor and Optimize: Continuously monitor performance data, conduct regular maintenance, and update programming as needed to maximize uptime and efficiency.

Manufacturers can connect with leading robotics suppliers or automation consultants for guidance. To identify service providers, consider searching terms such as “automotive robotics integrator” or “industrial automation consultant,” and verify their credentials, customer reviews, and industry experience before engagement.

Case Studies and Real-World Examples

Several global automotive leaders have demonstrated the value of robotic integration:

- Ford: Ford’s use of cobots in component assembly lines has improved both productivity and ergonomic safety for workers. The company continues to expand robotics across multiple facilities worldwide [5] .

- Toyota: Toyota’s commitment to the “Toyota Production System” includes extensive use of robotics for welding, painting, and quality inspection, resulting in highly reliable vehicles and efficient operations.

- General Motors: GM employs advanced robotic systems for machine tending, material handling, and automated inspection, contributing to its leadership in quality and innovation [4] .

Potential Challenges and Solutions

While robotics bring many advantages, manufacturers may encounter several challenges:

- High Initial Investment: Upfront costs for robotics systems can be significant. Many companies offset this by starting with targeted automation in high-impact areas and expanding gradually as ROI is demonstrated.

- Workforce Adaptation: Employees may require retraining to work with and maintain robotic systems. Proactive training programs and clear communication about job evolution can ease this transition.

- Integration Complexity: Customizing robots to handle varying part sizes and materials can be complex. Working with experienced integrators and leveraging modular, reprogrammable robots can help address these challenges [1] .

- Maintenance and Downtime: Robots require regular maintenance to ensure uptime. Implementing predictive maintenance and monitoring systems helps minimize unexpected breakdowns.

Alternative Approaches and Emerging Trends

Some manufacturers may not be ready for full-scale robotic automation. Alternative strategies include:

- Incremental Automation: Automate one process at a time, focusing on the most repetitive or hazardous tasks first.

- Hybrid Work Cells: Combine human and robotic labor in shared workspaces to maximize flexibility and efficiency, especially in final assembly and inspection.

- Outsourcing: For specialized automation needs, partner with contract manufacturers or third-party automation providers.

Emerging trends include the use of artificial intelligence for adaptive robotics, increased connectivity via the Industrial Internet of Things (IIoT), and enhanced data analytics for process optimization. Staying up to date with industry publications and participating in trade shows can help manufacturers identify new opportunities.

How to Access Robotic Solutions for Automotive Assembly

For organizations seeking to implement robotics, several practical steps are recommended:

- Contact reputable automation integrators or robotics manufacturers with experience in automotive applications. Inquire about successful implementations, reference projects, and support services.

- Consult with industry associations such as the Association for Advancing Automation (A3) for guidance, training resources, and directories of certified providers.

- Attend industry conferences and expositions to see demonstrations of the latest robotic technologies and network with experts in the field.

- Search for government or industry programs that may offer grants or incentives for automation and technology upgrades. For U.S. companies, you can visit the official U.S. Department of Commerce website and search for “manufacturing innovation grants.”

Before making investment decisions, request detailed proposals, conduct site visits to existing installations, and compare multiple solution providers. Ensure all equipment complies with relevant safety standards and supports future scalability.

Conclusion

The role of robotics in automotive assembly lines is expanding rapidly, offering unprecedented gains in efficiency, quality, and workplace safety. By understanding the available technologies, implementation strategies, and potential challenges, manufacturers can position themselves for long-term success in a competitive global market.

References

- [1] Wevolver (2023). Automotive Robots: Revolutionizing the Assembly Line.

- [2] Wes-Tech (2023). How Specialized Robots are Driving Automotive Manufacturing.

- [3] Assembly Magazine (2022). Beyond the Welding Line: Robots and Automotive Assembly.

- [4] Acieta (2023). Automotive Manufacturing Robots.

- [5] Proven Robotics (2023). How Are Robots Used in Assembly Lines? 10 Efficient Applications.

MORE FROM smartsavingsfinder.com