Revolutionizing Vehicle Design: The Critical Role of Lightweight Materials

Photo by Sai Kalyan Achanta on Unsplash

Introduction: The Shift Toward Lightweight Vehicle Design

In the evolving landscape of automotive engineering, the use of lightweight materials has emerged as a cornerstone of modern vehicle design. This approach not only enhances performance and safety but also addresses urgent concerns such as fuel efficiency and environmental sustainability. As regulatory standards become more stringent and consumer demand for efficient vehicles grows, manufacturers around the world are accelerating their adoption of advanced lightweight materials. This article explores the importance of these materials, their benefits and challenges, and provides actionable guidance for industry professionals and consumers alike.

Key Benefits of Lightweight Materials in Automotive Design

1. Improved Fuel Efficiency and Environmental Impact

Reducing vehicle weight directly translates to lower energy consumption. According to the U.S. Department of Energy, a 10% reduction in vehicle weight can result in a 6% to 8% improvement in fuel economy. This has a substantial impact on both operating costs and carbon emissions. For example, replacing traditional steel components with high-strength steel, aluminum alloys, or composites can decrease the weight of a vehicle’s body and chassis by up to 50%, significantly reducing fuel consumption and enabling compliance with increasingly strict emission standards. The adoption of these materials in just a quarter of the U.S. vehicle fleet could save more than 5 billion gallons of fuel annually by 2030 [1] .

2. Enhanced Safety and Performance

Contrary to common misconceptions, lighter vehicles can be safer. Advanced lightweight materials such as high-strength steel and composites improve structural performance, particularly in crash scenarios. These materials allow for better crumple zones that absorb impact energy more effectively, reducing the risk of injury to occupants. Vehicles constructed with lightweight materials also benefit from improved handling and braking, as the enhanced power-to-weight ratio makes them easier to maneuver and control. The BMW i3, which employs carbon fiber-reinforced plastics, exemplifies how lightweighting does not compromise safety or comfort [2] .

3. Lower Operating and Maintenance Costs

Lightweight materials such as aluminum and composites offer superior corrosion resistance compared to traditional steel. This translates into longer vehicle lifespans, lower maintenance costs, and increased resale value. For instance, corrosion costs Americans over $23 billion each year; switching to more resistant materials can dramatically reduce these expenses [2] . Additionally, improved fuel economy directly leads to significant annual savings for both private owners and fleet operators, supporting a lower total cost of ownership.

4. Enabling Electric and Hybrid Vehicle Innovation

Lightweight materials are especially crucial for electric and hybrid vehicles, which often carry heavy battery packs and advanced powertrains. By reducing the overall vehicle mass, manufacturers can offset the added weight of batteries, maintain or extend driving range, and even downsize battery requirements. This not only improves efficiency but also helps lower the cost and environmental impact of producing electric vehicles [1] .

Types of Lightweight Materials and Their Applications

The automotive industry utilizes a range of advanced materials to meet lightweighting goals. Key examples include:

Photo by Ildar Garifullin on Unsplash

- Advanced High-Strength Steel (AHSS): Offers strong strength-to-weight ratios and is widely used for safety components, chassis, and structural elements. AHSS enables significant weight reduction without compromising structural integrity [3] .

- Aluminum Alloys: Known for corrosion resistance, low density, and recyclability, aluminum is extensively used in body panels, engine parts, and wheels. Substituting aluminum for steel can reduce specific component weights by up to 50% [1] .

- Magnesium Alloys: Even lighter than aluminum, magnesium alloys are used in specialized parts such as transmission cases and steering wheels. While they present challenges in terms of cost and manufacturability, ongoing research is expanding their use [4] .

- Carbon Fiber and Polymer Composites: These materials provide exceptional strength-to-weight ratios and design flexibility, making them ideal for high-performance and luxury vehicles. Their use is expanding as production techniques become more cost-effective [2] .

Implementation: How Manufacturers and Consumers Can Access Lightweight Innovations

Automotive manufacturers are rapidly incorporating lightweight materials into new models. If you are an industry professional seeking to adopt these innovations, consider the following steps:

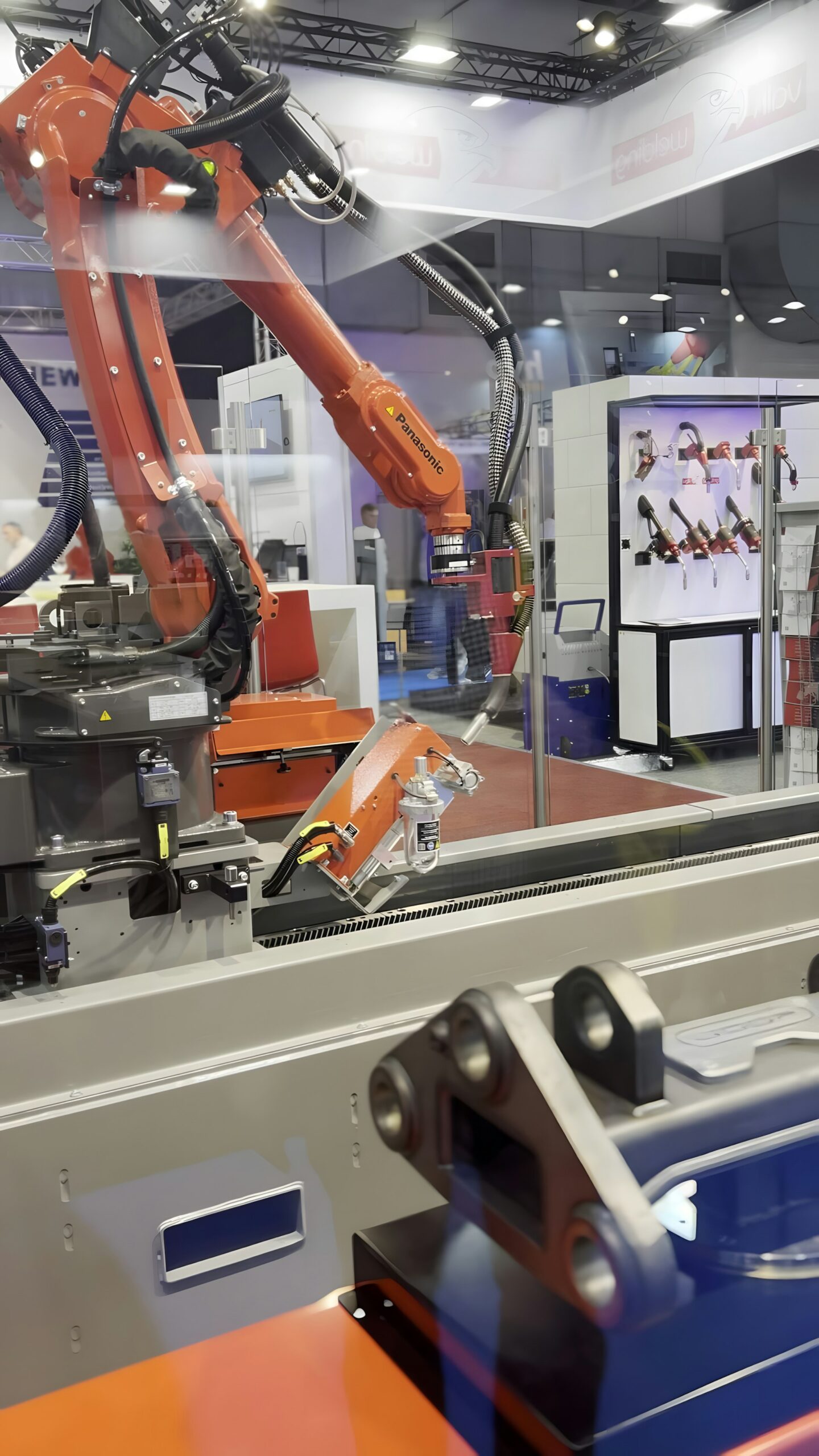

- Engage with material suppliers specializing in advanced alloys, composites, and sustainable alternatives. Attend industry expos and technical conferences to stay current on the latest offerings.

- Collaborate with research institutions and government initiatives focused on automotive lightweighting. The U.S. Department of Energy’s Vehicle Technologies Office funds research and provides resources-visit the official Department of Energy website and search for “Vehicle Technologies Office lightweight materials” for current grant opportunities and technical guidance.

- Integrate lightweighting into the early stages of vehicle design. Use computer-aided engineering (CAE) tools to simulate material performance and optimize structural layouts.

- Educate consumers about the benefits of lightweight vehicles, including lower fuel costs and improved safety. Provide transparent data on material choices and their impact on vehicle performance.

For consumers interested in purchasing vehicles that incorporate these technologies, you can:

- Research vehicle specifications through manufacturer websites and third-party automotive review platforms. Look for details about the use of aluminum, high-strength steel, or composites in body and chassis construction.

- Consult dealership professionals for information on models emphasizing fuel efficiency and advanced materials.

- Participate in test drives to experience the handling and comfort differences provided by lightweight design.

If you want to stay updated on the latest in lightweight automotive innovation, consider subscribing to reputable automotive publications or attending public auto shows that highlight sustainable vehicle technologies.

Challenges and Solutions in Adopting Lightweight Materials

While the advantages of lightweight materials are clear, several challenges exist:

- Cost: Advanced materials such as carbon fiber and magnesium alloys are often more expensive than traditional steel. Manufacturers can address this by adopting high-strength steel or aluminum in high-volume components, where costs are lower, or by using tailored composites for critical applications only [3] .

- Manufacturing Complexity: New materials may require specialized forming, joining, or repair processes. Investing in workforce training and advanced manufacturing technologies can help overcome these barriers.

- Consumer Perception: Some buyers may be unfamiliar with the benefits of lightweight materials or may perceive them as less durable. Clear communication of safety, longevity, and performance advantages is vital for market acceptance.

- Supply Chain Limitations: Sourcing advanced materials can be challenging due to limited suppliers or geopolitical risks. Building diversified supply chains and collaborating with multiple partners can mitigate these risks.

Real-World Examples and Case Studies

Automakers worldwide are investing heavily in lightweight vehicle design. For instance, Ford’s F-150 pickup incorporates an aluminum body that reduces curb weight by more than 500 pounds compared to previous models, leading to significant gains in fuel economy and payload capacity. Similarly, BMW’s i3 electric vehicle features a passenger cell made almost entirely from carbon fiber-reinforced polymer, demonstrating how advanced materials can deliver both weight savings and structural strength [2] .

According to a recent market research report, the global automotive lightweight materials market is expected to grow at a compound annual growth rate (CAGR) of 7.3% from 2023 to 2029, with projected revenues exceeding $1.3 trillion by 2029. This trend underscores the industry’s commitment to innovation and the growing accessibility of lightweight technologies for both manufacturers and consumers [4] .

Step-by-Step Guidance for Accessing Lightweight Vehicle Solutions

If you are considering a transition to lightweight vehicles-whether as a manufacturer, fleet manager, or consumer-you can take the following steps:

- Identify your primary objectives (fuel savings, lower emissions, performance, etc.) and research the best-fit lightweight material solutions for your needs.

- Consult automotive engineers or material science professionals for technical assessments. Many universities and technical institutes offer consultancy services for businesses.

- Engage with reputable dealerships and request detailed information on the materials used in various models.

- For large fleets, initiate pilot projects with lightweight models and track performance and cost metrics over time to validate projected benefits.

- Stay informed through industry publications, research reports, and government agency updates to learn about new lightweighting breakthroughs and upcoming incentives.

If you are looking for government or institutional support, search for “automotive lightweighting incentives” or “energy efficiency vehicle grants” on the official websites of the U.S. Department of Energy or your local energy authority. These agencies may offer funding, technical assistance, or demonstration projects relevant to your goals.

Key Takeaways

The integration of lightweight materials in vehicle design is reshaping the automotive industry by delivering tangible benefits in efficiency, safety, and sustainability. Both manufacturers and consumers can leverage these advancements to drive progress toward a cleaner, safer, and more cost-effective transportation future. As new materials and technologies continue to emerge, staying informed and proactive is essential for maximizing the opportunities presented by lightweight vehicle innovation.

References

- [1] U.S. Department of Energy (2023). Lightweight Materials for Cars and Trucks.

- [2] Motor (2025). The Integration of Lightweight, Sustainable Materials in Automotive Design.

- [3] Mayco International (2024). Driving Lighter: The Rise of Lightweight Cars in Automotive Innovation.

- [4] RPWORLD (2023). Driving Efficiency: Exploring Lightweight Materials in Automotive Applications.

MORE FROM smartsavingsfinder.com